Until the beginning of the 1980s, surface texture characterization was based exclusively on 2D profilometry. Then came the dawn of surface measuring instruments such as 3D profilometers. François Blateyron, Digital Surf’s senior expert on surface metrology, examines the next big change in surface analysis – freeform surfaces – and discusses current and upcoming tools available for studying them with Mountains®.

Most engineers and designers of mechanical components know roughness specifications through profile parameters, such as Ra. Many metrologists in the industry control surface texture specifications using a stylus profilometer that measures heights along a profile. This is fine as long as the texture is simple enough and homogeneous enough. But more and more, engineered surfaces have patterns, structures or specific texture printed, added or implanted on them, in order to better control surface function (adhesion, lubrication, hydrophobicity etc.) Specifications on such surfaces are more reliable and representative if they use areal parameters calculated on surfaces. The introduction of areal surface metrology was an important turning point in the 1990s.

However, the true complexity of a real surface may not even always be fully captured with a standard surface, coded on a matrix of heights. When the surface has complex form and superimposed small texture, or when the manufacturing process creates spatter particles or cavities, or when you are interested in characterizing roughness on the vertical wall of a rectangular trench, an acquisition along the Z-axis will result in lost information. So, what’s the solution? Freeform surfaces are the next paradigm shift.

Definition of a freeform surface (shell)

In order to keep surface information intact during acquisition and analysis, it is necessary to move the data structure from a function z=f(x,y), where one height value is coded for every x,y position on a regular grid, to a curvilinear form, (x,y,z)=f(u,v), where points in space are connected to their neighbors as triangles.

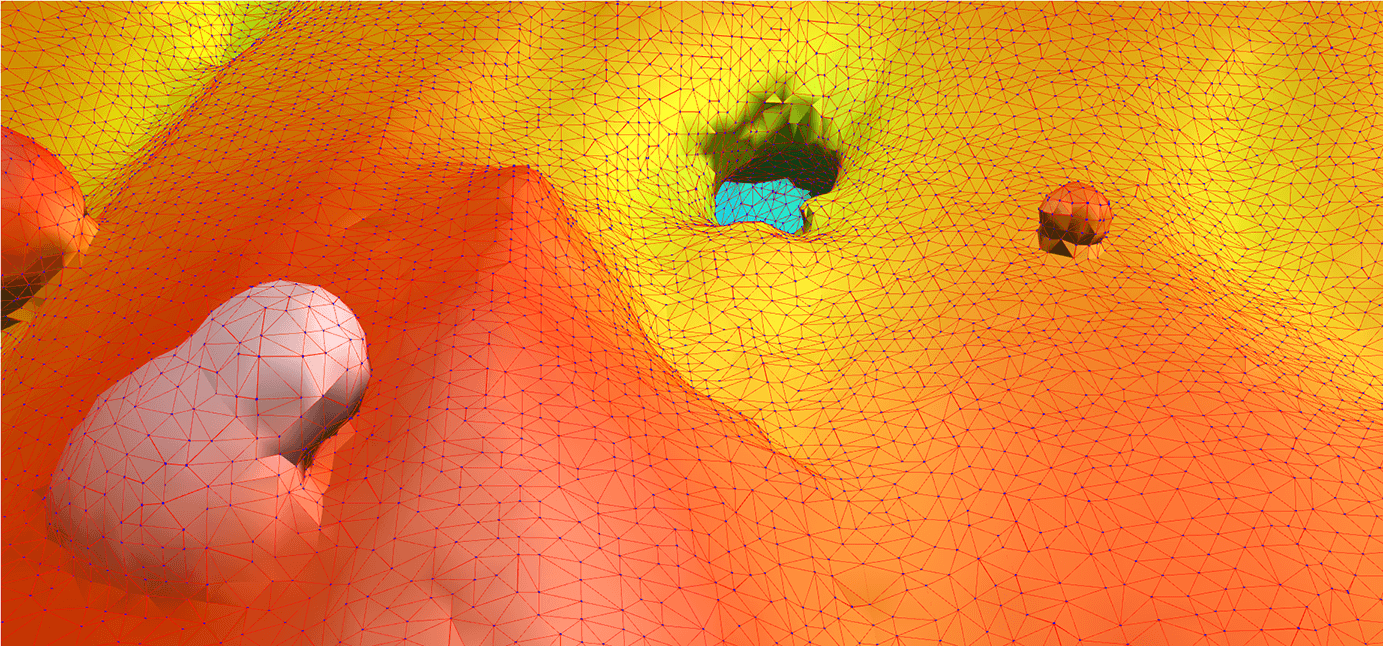

A freeform surface, called a “shell” in Mountains® (for reasons of brevity and because it corresponds to the outer envelope of a 3D object), is a point cloud (x,y,z) associated with connectivity information so that all points are connected in a triangle mesh in space. That way, the complete surface around an object can be coded. This also allows coding of undercut structures or internal cavities.

Above. 3D view in Mountains® of a shell (or freeform surface) of metallic powder melted by a laser in additive manufacturing. Non-melted powder particles are visible above the surface, as well as a cavity below the surface. The triangle mesh and points have been overlaid on a colored surface.

Triangle meshes are commonly used in dimensional metrology to represent, for example, a mechanical workpiece measured by a coordinate measuring machine (CMM). The difference here is that resolution has to be fine enough to allow surface texture analysis at the micrometer scale.

Mountains® 8 is compatible with freeform data structures and version 8.1 contains some new features. These form the basis of a future ecosystem around freeform surfaces (shells) which will be further developed and improved in subsequent versions.

Acquisition & processing of freeform surfaces

Freeform surfaces can be produced using several instrument techniques:

- Optical profilometry (confocal, interferometer, focus variation etc.): multiple acquisitions are performed at different angles, then partial height maps (standard surfaces) are stitched together into a single mesh in space.

- Scanning electron microscopy (SEM): images are processed by pairs; reconstructed height maps are stitched together.

- X-ray computer tomography (XCT): an interfacial surface is extracted from a voxel cube.

- µCMM or 3D scanner: a point cloud of sufficient density is meshed into a freeform surface under certain convexity conditions.

Mountains® 8 can load freeform surfaces from various file formats (STL, 3MF, OBJ, PLY). They are loaded as “shell” studiables and can be displayed in an interactive 3D view and further analyzed with Operators and Studies.

Besides coordinates and connectivity information, a shell studiable may also contain additional information, called attributes, created during acquisition or extraction, or generated by a specific Operator in Mountains®. These attributes may be color or intensity values, normal vectors, distance values from the reference surface, or any application-oriented attribute that needs to be linked to the shell studiable. An attribute can be associated with points or triangles, or even edges.

Bridge with XCT data

A bridge between the DigiXCT® software from Digisens and Mountains® is currently under development. This will enable extraction of accurate freeform surfaces from the density information contained in volume datasets and importation into Mountains® for surface texture analysis. The link to the original volume dataset will be maintained over time.

Note: Digisens specializes in the management and analysis of XCT datasets for inspection and metrology. www.digisens3d.com

Current Mountains® tools

Mountains® 8.0 already included two Operators for processing freeform surfaces:

The first one intersects the freeform surface with an oriented plane in order to create a contour profile that can be analyzed. This can be useful, for example, for checking angles and dimensions or even comparing the profile with a DXF model.

The second one allows the user to orient the freeform surface and position a rectangle to define the portion of the freeform surface to extract and convert to a standard surface. Useful, for example, when analyzing roughness on an internal surface (e.g. the internal surface of the chamber of a pump produced by additive manufacturing that cannot be accessed by regular profiler unless the workpiece is cut).

New plug-ins for surface texture parameters on a freeform surface

Digital Surf has been partnering with the Center of Precision Technologies (CPT) at the University of Huddersfield (UK) to develop a set of surface texture parameters calculated on freeform surfaces.

A team of talented researchers and PhD students at Huddersfield have developed the background mathematics and adapted the definitions of areal surface texture parameters to apply them to freeform surfaces.

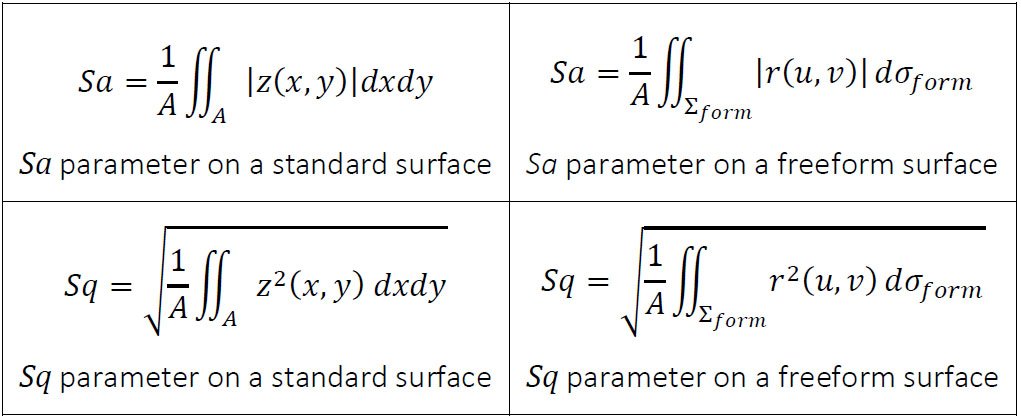

A symmetrical expression can be found for most parameters on freeform surfaces compared to standard surfaces:

where Σform represents the form surface which acts as a reference surface from which the deviations r(u,v) are measured between each point of the freeform surface and the form surface that is associated with it.

Mathematical details can be found in the paper: Pagani L, Qi Q, Jiang XQ, Scott PJ, Towards a new definition of areal surface texture parameters on freeform surface, Measurement 2017.

Mountains® 8.1 will introduce a plugin that calculates a subset of ISO 25178-2 parameters directly on a loaded freeform surface, without the need to convert it to a standard surface.

Parameters are calculated from the form deviation values associated with each point of the freeform surface. This means that a form surface has to be associated with a freeform surface. This is done through a dedicated plugin operator that fits a least-square form to the point cloud. The form can be a plane, polynomial, cylinder or sphere. This is a preliminary stage before parameters can be calculated.

Further developments on the subject will be made in subsequent versions and some will be made available as optional modules.

Advanced analysis: CAD compare, filters and more

In the case of an additive manufactured component, it is usually necessary to fit a CAD model or the designed mesh to the freeform surface under test. Such fitting is complex and computer-intensive. When no model is available, the reference surface may be approximated using a low-pass filter (S-Filter), the same way a waviness surface is used as the reference surface to calculate roughness heights. Smoothing filters as well as some morphological or envelope filters and retouch tools can also be useful. These functions will be available in future versions.

As a leading product for surface texture analysis, Mountains® embraces the next revolution in metrology and is committed to providing the tools necessary to users in industry and research. Initial feedback on these applications provided by users will help validate tools and prepare the forthcoming standardization. You could say Digital Surf is preparing the future with key partners and that some of this future is already available in Mountains® 8.1.

MountainsMap® Premium, MountainsSEM® Premium and MountainsLab® Premium all include the Shell Extension module that adds features for freeform surfaces. The module is also available as an option with other products.

Author : François Blateyron

Resources :

Introduction to shell data: digitalsurf.com/blog/what-is-a-shell-or-freeform-surface

Shell Extension module: digitalsurf.com/optional-modules/shell-extension

CPT at Huddersfield University: research.hud.ac.uk/institutes-centres/cpt

Read more on freeform surfaces: www.elsevier.com/books/advanced-metrology/jiang/978-0-12-821815-0