Researchers from the Future Metrology Hub at the University of Huddersfield have developed a radically simplified head-up display (HUD) system that relies on just one freeform mirror. While conducting this study, they turned to MountainsMap® software to verify the critical surface quality of the optical component.

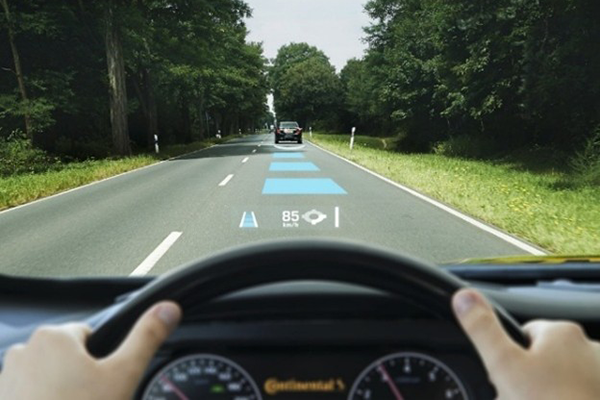

Head-up displays, widely used in aviation and increasingly in automotive dashboards, traditionally require several optical elements to fold and relay the image from the display to the driver’s or pilot’s line of sight. This makes them bulky, power-hungry and sensitive to alignment errors.

The Huddersfield team set out to design a HUD that eliminates this complexity. Their solution: a single, carefully shaped freeform mirror that both redirects the image and corrects for off-axis aberrations.

Above. The Huddersfield team involved in the study. From left to right: Dr. Wenbin Zhong, Prof. Paul Scott, Prof. Dame Xiangqian Jiang, Dr. Wenhan Zeng, Dr. Sumit Kumar.

From concept to mirror

Using optical design software, the researchers optimized a freeform mirror shape capable of delivering a wide, stable “eyebox” ie. the volume in which the observer’s eye can move while still seeing the full image.

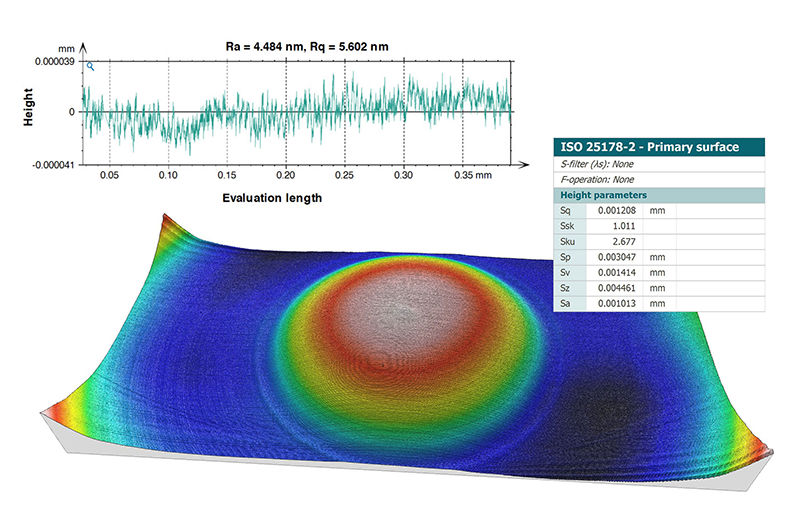

The next challenge was fabrication. The mirror was produced using ultra-precision single-point diamond turning, with on-machine metrology providing feedback during cutting. This allowed the team to achieve sub-micron form accuracy and nanometer-scale surface finish, prerequisites for high optical performance.

MountainsMap® for verification

To validate the mirror surface, the team used MountainsMap® software for post-measurement analysis. Surface data collected during and after machining was imported into MountainsMap®, where levelling and form removal were performed. This enabled the researchers to isolate the residual roughness and assess whether the manufactured surface matched the intended design.

According to Dr. Wenhan Zeng, one of the researchers involved in the study, this step was essential: “By quantifying roughness parameters and visualizing the deviations, we were able to confirm that the freeform mirror would deliver the required optical quality.”

Above. Surface roughness plot and form error (shown in 3D view with corresponding parameters table) of one of the freeform mirror prototypes developed as part of the study.

Compact, robust and promising

The prototype HUD showed excellent performance. Despite using only one mirror, the system delivered sharp imagery across a wide eyebox, maintaining image quality even when the observer’s head height varied. The simplified design also reduces alignment sensitivity and eliminates moving parts, promising a more compact and energy-efficient HUD.

This case study illustrates not only the potential of freeform optics in reshaping display systems, but also the indispensable role of surface analysis tools like MountainsMap® in bridging the gap between theoretical design and functional device.

Instrument & Software used

Confocal microscope & MountainsMap® software

Read more

Sumit Kumar, Wenbin Zhong, James Williamson, Prashant Kumar, Thomas Furness, Shan Lou, Wenhan Zeng, Xiangqian Jiang, Design, fabrication, and testing of freeform mirror-based head-up display system, Optics & Laser Technology, Volume 186, 2025, 112653, ISSN 0030-3992, https://doi.org/10.1016/j.optlastec.2025.112653.