Beauty giant L’Oréal has gained a reputation over the years for attaching great importance to research and innovation. The Advanced Research Division, located just outside Paris (France), is at the heart of that particular component of the company’s mission. One of the many subjects studied by the division’s team of specialized researchers is the constant improvement of sunscreens. Florian Formanek, head of the Microscopy & Microanalysis Laboratory, tells us more.

Photoprotection – a key cosmetic segment

SPF, or Sun Protection Factor, is a measure of the efficacy of sunscreens to protect skin against harmful UV radiation. The approved method for SPF determination is through the in vivo monitoring of erythema (reddening) caused on human skin by solar-simulated sunlight.

However, alternative in vitro measurements exist and are performed by diffuse UV transmission spectroscopy through a sunscreen-covered substrate, such as rough PMMA (polymethyl methacrylate) plates which mimic skin texture and surface free energy.

Cosmetic formulations usually contain several chemical (organic) and physical (inorganic) filters that either reflect, scatter or absorb UVA and UVB radiation to offer an efficient broad-spectrum protection. Other ingredients include water, glycerin (moisturizer), emollients (for smoothing properties), emulsifiers (to mix water with oil), thickeners (to confer viscosity), film formers (water resistancy) and sensory enhancers.

Besides obvious parameters such as film thickness and homogeneity, sunscreen performance can also be affected by the localization of the different filters within the bulk. Depending on the physicochemical properties of the substrate surface, processes like coalescence, dewetting or phase migration occur upon drying and evaporation of volatile compounds, thus impacting the distribution of filters as well as aqueous/oily phases.

We employ Raman imaging in combination with other microscopy techniques to better understand the distribution of UV filters in various formulation bases and compare with in vitro SPF assessment.

Experiments and data processing

A Renishaw inViaTM QontorTM Raman microscope equipped with a 532 nm laser is used to acquire 3D or 4D hyperspectral maps containing – at each pixel – a Raman spectrum in the fingerprint region (400-2000 cm-1). A recently introduced real-time focus tracking unit simultaneously provides the topography of the sample surface with micrometric axial resolution.

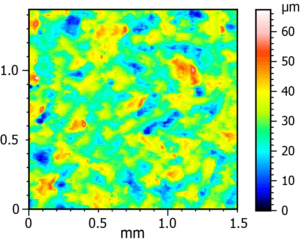

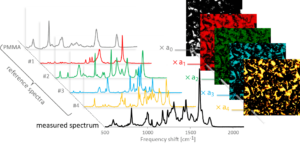

Figure 1. 3D height profile of a bare PMMA plate with theoretical Sq roughness of 6.6 μm, measured with Mountains® at 6.18 μm. Figure 2. Principle of the spectral decomposition processing to retrieve the relative contribution of the different compounds in the formulation.

We use Mountains® software firstly to remove outliers (non-measured points obtained during auto-focus), then to compensate the general slope of the sample with the leveling or form removal functions. The next step is to perform morphological filtering, before employing advanced analysis methods.

The colocalization module allows us to overlay the relief map with 2D chemical images obtained after chemometric processing of spectroscopy information. Part of this processing involves the deconvolution of measured spectrum using reference spectra of each individual ingredient, to extract their relative concentration at the laser focus spot.

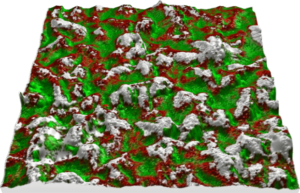

Figure 3. Reconstructed view of a sunscreen-covered PMMA plate, combining topographic and chemical data. • 10% height amplification was applied to enhance 3D rendering • Gray areas show uncovered PMMA regions, red and green areas reveal the distribution of two different UV filters. • Calculated Sz parameters (67.4 μm→ 50.3 μm) indicate smoothing of the surface through filling of the valleys by the cream.

Other usages of Mountains® for our applications include extracting quantitative surface textures from 3D samples (hair, skin, nail, materials) measured by optical profilometry, optical coherence tomography (OCT) or fringe projection, producing stereo views from tilted scanning electron microscopy (SEM) images as well as extracting and processing intensity profiles from energy-dispersive X-ray (EDX) spectroscopic data generated on SEM and TEM.

Further reading

Importance of sunscreen products spreading protocol and substrate roughness for in vitro sun protection factor assessment, L. Fageon, D. Moyal, J. Coutet and D. Candau. International Journal of Cosmetic Science, 2009, 31, 405–417. dx.doi.org/10.1111/j.1468-2494.2009.00524.x

Repartition of oil miscible and water soluble UV filters in an applied sunscreen film determined by confocal Raman microspectroscopy, M. Sohn, T. Buehler and G. Imanidis. Photochemical & Photobiological Sciences, 2016, 15, 861-71. dx.doi.org/10.1039/c6pp00024j

Instruments & software used

Renishaw inViaTM QontorTM Raman microscope + MountainsMap® software [Note, in version 9, these features are available in the MountainsSpectral® range].