Have you ever heard of the Sdr parameter? What if it turned out to be the ideal indicator for characterizing the functionality of your surface data?

In this article, several Mountains® users share with us the benefits of studying the correlation between the developed surface area and surface functionalities including wettability, adhesion and conductivity.

So, to start with, what is Sdr?

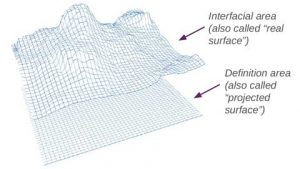

To give a basic definition, the Sdr parameter can be considered as the ratio between the area of the “real” developed surface and the area of the “projected” surface. This ratio is sometimes called the “complexity” of the surface.

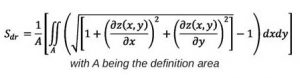

In the ISO 25178 standard, Sdr is defined by the following formula:

Case study 1: adhesion & conductivity in the electronics industry

The Sdr parameter has a important role to play in controlling surface properties of materials in electronics manufacturing.

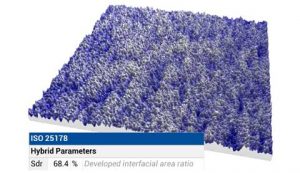

Roy Li, application specialist at Carl Zeiss (Shanghai) told Surface newsletter “Customers in the printed circuit board (PCB) industry are using the developed interfacial area ratio as one of the key parameters for measuring the performance of brown oxide treatment.”

“The purpose of brown oxide treatment on PCBs is to create a uniform layer of organic metal complex on copper surfaces to increase roughness and adhesion.”

Sdr calculated on a surface treated with brown oxide

High frequency electrical conductivity is another functionality which must be evaluated within the electronics industry.

“We manufacture electro-deposited copper foil which has a wide range of applications in electronics” said Bodo Gemsleben of Circuit Foil Luxembourg.

“At higher frequencies electrical signals are only conductive at the surface and no longer inside the copper tracks. For such applications, our customers often need to obtain lower surface roughness. However they also have to maintain high adhesion between the copper and the substrate materials (e.g. low-loss resins) in order to minimize the so-called conductor loss.”

“The Sdr parameter, in combination with Sa and Sq, is especially useful for describing the surface in this case.”

Case study 2: industrial coatings

Coating adhesion on mechanical workpieces can be studied using the Sdr parameter.

Another example of use of the Sdr parameter is from the tool manufacturing industry. Daan Boden, PhD student in industrial engineering working at Atlas Copco (an air compressor manufacturing company) tells us more: “One of our specialties is oil-free compressors, the rotors and casing of which must be coated. To ensure coating adhesion, the surface must be made rougher (this is done with sand-blasting).”

“The forms of our workpieces are quite complex and the dimensions are rather big. We decided to use the Sdr parameter after performing optical measurement of these, as it is the areal variant of the Plo parameter (developed length).”

Case study 3: biofilm wettability

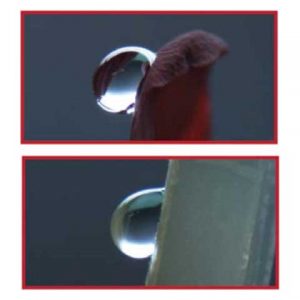

Top: rose petal. Bottom: hydrophobic biofilm. The Sdr values of the two surfaces are very close.

Carolina Falcón García, Professor in Biomechanics at the Technical University of Munich (Institute of Medical Engineering), is using µsoft software from Nanofocus based on Mountains® technology to study the surface properties of biofilms. “The colonization of surfaces by bacterial biofilms constitutes a huge problem in healthcare and industry.” explains Carolina. “When attempting biofilm inactivation or removal, it is crucial to sufficiently wet the biofilm surface with antibacterial agents. However, certain biofilms efficiently resist wetting and the origin of this behavior remains to date unclear.”

“We discovered that the Sq value, which is generally accepted as a measure of the roughness of a surface, was not sufficient in describing the complexity of these biosurfaces. We found that Sdr was the actually the most accurate parameter for doing this. Using Sdr in combination with contact angle measurements, we were able to easily distinguish between a hydrophilic surface and two types of hydrophobic biofilm surfaces.”

“In a recent study, we found that the Sdr values we obtained for the peripheral region of one biofilm were very close to the values we obtain for rose petals. This further underscored the analogy drawn between the wetting resistance of rose petals and that of one of the hydrophobic biofilms.”

How to get the most out of the Sdr parameter

According to the definition in the ISO 25178 standard, the Sdr value should be calculated on the scale-limited surface ie. the S-F or S-L surface. This means that the microroughness should be removed, as well as the nominal form.

The Sdr parameter is heavily influenced by the spatial resolution of the instrument, which depends on the x,y spacing between measured points and on the type and metrological characteristics of the sensor (numerical aperture, tip radius etc.)

The Sdr parameter (and the value of the developed area and projected area) is available in MountainsMap® Premium, as well as in the 3D Advanced Surface Texture and the new Scale-sensitive analysis modules (see pages 2-3).

Author : Isabelle Cauwet, applications and support manager

Resources :

Read more on surface parameters in the Surface Metrology Guide