Newsletter

Stay up to-date with the latest imaging, analysis and metrology news from Digital Surf.

SEM image colorization & enhancement

Colorize SEM images easily:

Learn more: wwww.digitalsurf.com/news/add-color-to-sem-images-in-only-a-few-steps/

Correct and enhance SEM images:

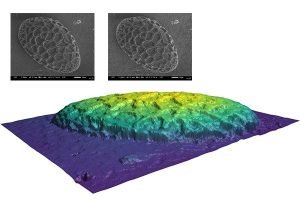

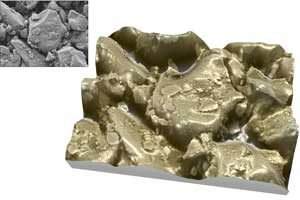

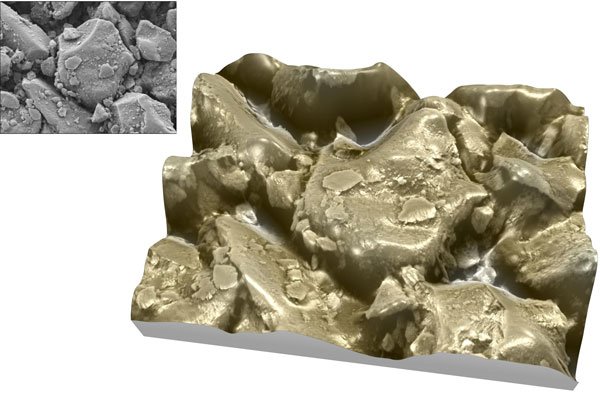

3D reconstruction from stereo pairs

Learn more: wwww.digitalsurf.com/blog/7-tips-for-producing-sem-stereo-pairs/

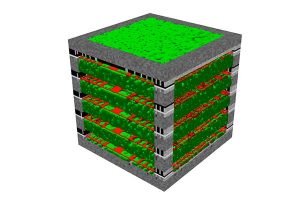

Reconstruct 3D surface topography from 4 images obtained using a four-quadrant detector.

3D reconstruction from 4 images

Learn more: wwww.digitalsurf.com/blog/using-a-four-quadrant-detector-in-3d-reconstruction/

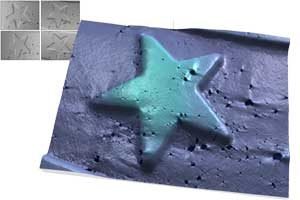

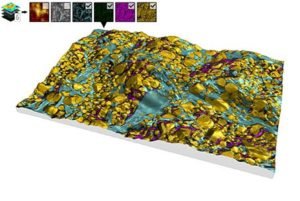

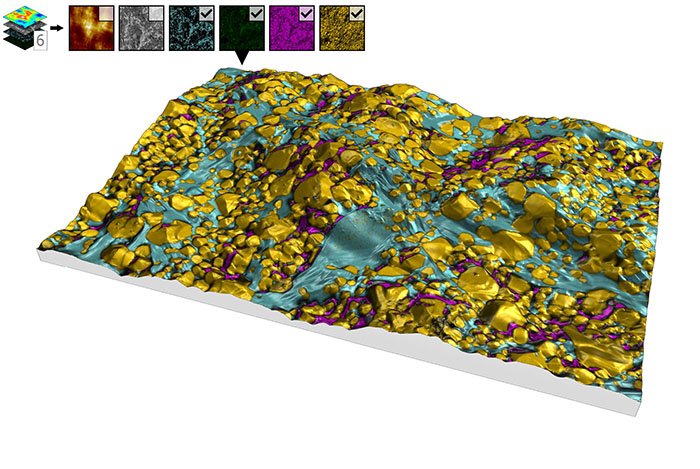

3D rendering from single images

Build spectacular 3D renderings associating EDS (EDX) maps or other spectral/compositional data with topography reconstructed from SEM images

Create 3D chemical maps with EDS data

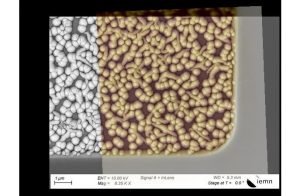

FIB-SEM tomography

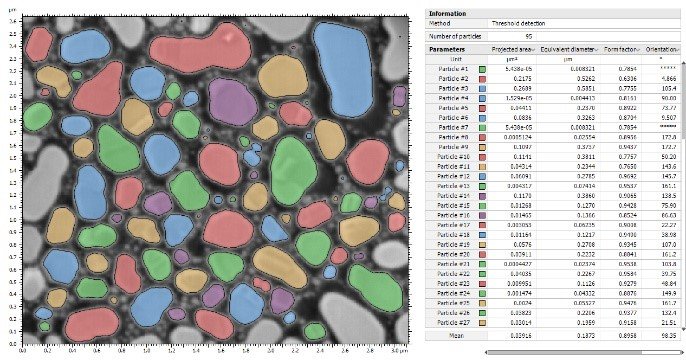

Apply powerful particle analysis tools to your SEM data and automatically identify and quantify features in your image using SEM-specific object recognition.

2D particle analysis

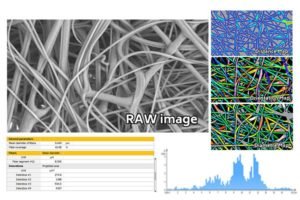

Fiber Analysis

Correlative analysis

Left: colocalization of an SEM image with AFM topography.

|

MountainsSEM® Premium |

MountainsSEM® Expert |

MountainsSEM® Color |

|---|---|---|---|

|

Instrument compatibility |

Any scanning electron microscope (SEM) |

||

Product features |

|||

|

Quick SEM image colorization |

|||

|

Basic analysis and measurement tools |

|||

|

Image correction & enhancement tools |

|||

|

Ultra-fast 3D reconstruction from 2 or 4 SEM images |

|||

|

Instant 3D enhancement of single SEM images |

|||

|

EDS/EDX map overlays on surface topography |

|||

Optional modules |

|||

|

Correlative Microscopy |

|||

|

2D particle analysis & characterization |

Option | Option | |

|

Fiber Analysis |

Option | Option | |

|

FIB-SEM tomography cubes visualization & analysis |

Option | ||

|

Contour analysis |

Option | Option | |

|

Support for Shells (freeform surfaces) |

Option | ||

|

Advanced profile analysis |

Option | Option | |

|

Advanced Topography Analysis |

Option | Option | |

|

Fourier & wavelets analysis |

Option | Option | |

|

Spectroscopy |

Option | Option | |

|

Thickness Analysis |

Option | Option | |

|

4D Surface Change |

Option | Option | |

The following range of optional modules for advanced and specialized applications is available for MountainsSEM®.